Building the Ultimate Scooter Cockpit

Harry Wills - Bo CTO - September 2025

Let’s Start from the Top

A recent visitor to the Bo workshop commented that “the 10,000 amazing details that make my Bo special simply aren’t being shared.”

We guess he’s not the only interested Bo rider, so I’ve written a short series to share a few of these stories.

This first one is about how we actually keep your hands connected to your premium electric scooter. Can there be such a thing as a premium scooter stem...

The part between your hands and your vehicle

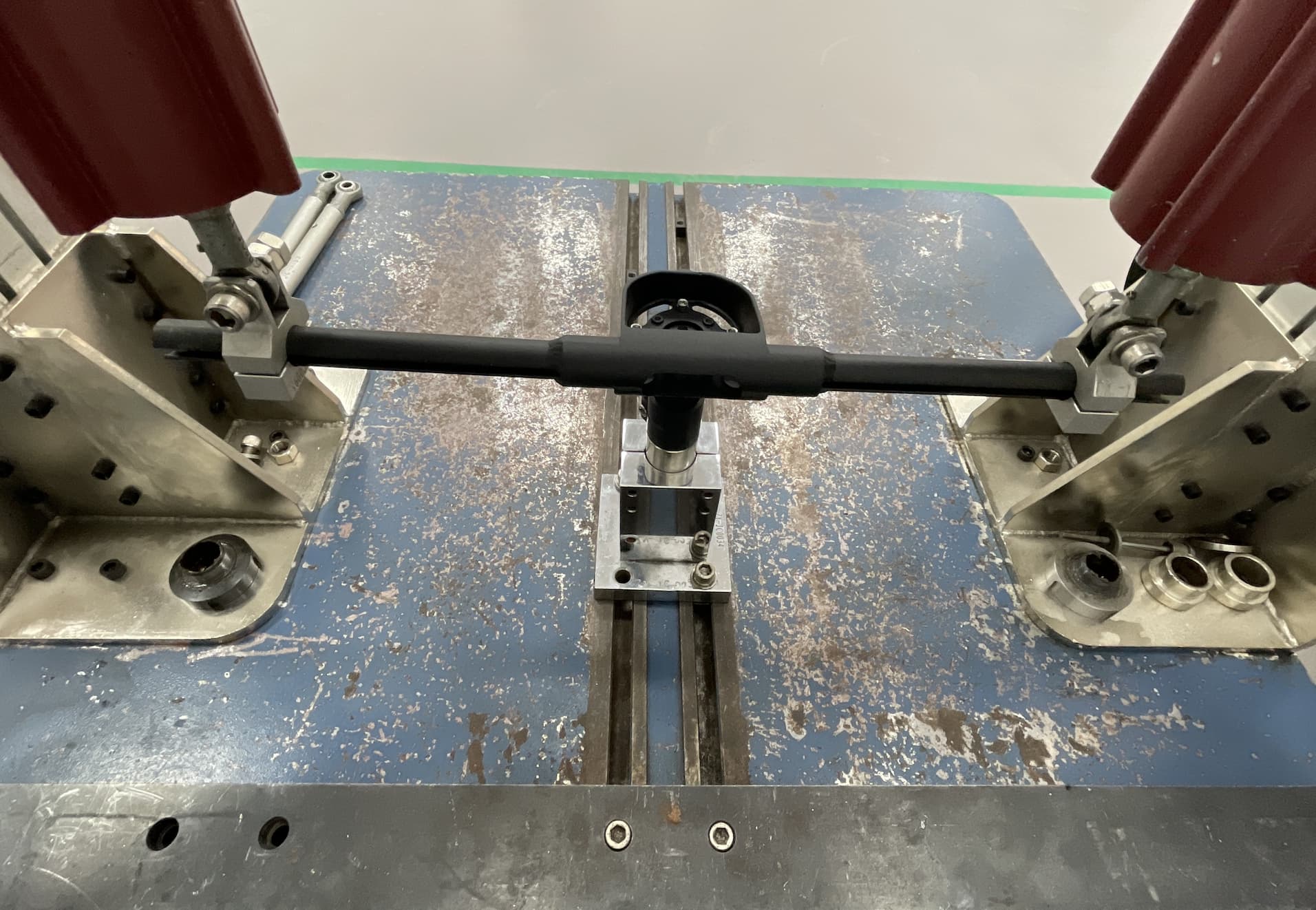

In the photo above, you’re looking at a forged aluminium Bo stem. Forming this piece involves a gigantic press slamming down onto a small disc of aluminium with nearly 600 tonnes of pressure. That’s hard to visualise, but imagine 450 cars stacked in a column on top of that one piece of metal; it gives you the general idea that there's a lot of force involved here.

The resulting billet isn’t perfect of course; that comes later. But there’s a very good reason we build this way. To set the context: this isn’t a toy, it’s a vehicle.

Forged for strength, and safety.

This stem is literally the only thing connecting your hands to the scooter. It sits between the handlebars, underneath those sleek plastic covers, and carries all the strain as you carve down the street or fly up hills.

When the giant press hammers down on the billet, it aligns the microscopic grain of the metal, expels air bubbles, and creates a solid, safety-critical part. This is how we make Bo one of the strongest and safest e-scooters for adults.

It’s not the cheapest method, and it’s not the same approach as you will find on budget scooters like Xiaomi, Kugoo, or Unagi. For those it is normally a low cost aluminium casting. But when safety matters, forging wins.

Cut to fit. Built to last.

Next, the forged lump gets precision-machined, carving away any material that is not contributing to the strength of the part.

Dozens of robotic cuts sculpt out lighting channels, brake mounts, internal cable routing and more. This is why Bo has no ugly zip ties, no bolt-on brackets, and no wobbly panels. It’s part of what makes Bo one of the cleanest-looking electric scooters in the UK or EU.

If you’re comparing Bo vs Segway, this is where the difference starts to show.

Brutal testing, because real roads are brutal.

After it’s cleaned and welded, the stem enters final testing. Paint is layered, baked and cured. Then the component is clamped into a test rig and it gets brutalised.

Two pneumatic rams hammer the handlebars 300,000 times (10x the industry requirement) to simulate years of real-world riding, potholes, braking, and the sort of hits most scooters aren’t designed for.

At the point where most of the lightweight commuter scooters on Amazon would fold in half, Bo doesn’t flinch. This vehicle means business.

This is just one part, but it shows the Bo approach.

Once approved for production, this stem becomes part of your ride. One of many forged, tested and over-engineered components that make up the Bo M: a high-end, road-legal electric scooter that genuinely feels built for the journey.

We could’ve taken shortcuts, we could’ve made it cheaper, heavier, or easier to manufacture. But then it wouldn’t be Bo. That’s why we can’t build a scooter for £300. It’s also why we don’t have to recall hundreds of thousands of units like others.

Next in this series: Over 100 LEDs and a lighting system that shows off.

In the next instalment, we’re lighting up with 100+ LEDs, dynamic startup animations, and race-inspired detailing.

Because if you’re building one of the best electric scooters in Europe, it should look the part, even when parked.